Car paint experts - since water-based automotive paint dry at room temperature

XiangYuan chemical automotive paint

1 car coating application background to talk about car coating, first to introduce a word - VOC (volatile organic compounds)

V - VOLATILE

O - ORGANIC

C - COMPOUND

VOC, nitrogen oxides, such as automobile exhaust and high intensity of light can lead to the formation of ozone (O ₃), ozone would gather in the tropopause is breathable, cause a harm to human respiratory system and nervous system. Therefore reduce the formation of ozone, is to reduce photochemical pollution, improve the quality of air and water quality, the important way to improve the quality of the overall environment.

After entering the 21st century, the global rapid development of auto industry, car coating also get rapid development, but at present, China's auto market after the car paint still is given priority to with traditional solvent, solvent coating contains a large number of VOC, not only to the painter's health in the process of coating has a certain influence, cause serious pollution to the ecological environment, bring great harm to human health. In order to meet the development requirements of The Times and meet environmental standards, automobile coating is to development of water-borne coatings, high solid and powder coating. New varieties of automotive coatings and coating process, "high-quality, environmental protection, energy saving, low cost" become the main melody of automotive coatings and coating development.

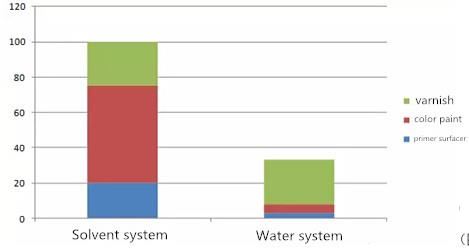

Compared with solvent paint, water-based paint the VOC content greatly reduce, due to the coating, paint, solid points is different, the amount of VOC coating production process have different influence degree.

Water-based system VOC reduction effect

Remark: Water-based varnish coat application is still not extensive, general recommendations with high solid varnish or UV coating

2 car repair coating application equipment and construction technology requirements

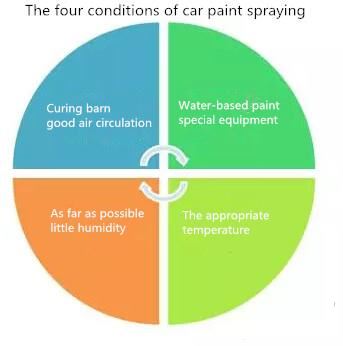

The four conditions of car paint spraying

1 spray room well ventilated, the air flow of about 18000 m3 / min, spray inside the wind speed is about

0.25 m/s advisable, ensure the water vapor in time taken away;

2 special water-based paint spray gun, spray gun with pressure gauge HVLP (low voltage high flow)

environmental protection spray gun, efficient atomization effect and low energy consumption;

3 bellow venturi ram, provide clean pouring and plenty of wind speed, speed up the evaporation;

4, construction conditions: the best construction environment, temperature: 20±5 ℃, humidity: ≤70%;

5, pressure: 3-5 kg/cm2.

6, the oil-water separator: adopt three oil-water separator, ensure clean air;

7 dry conditions

Under normal temperature with blow as you about 10 minutes, or proper heating can speed up the drying speed, after paint film on the surface of the matte, but add to spray the varnish coat.

To explore the DISCOVERY

XiangYuan chemical car water-based automotive repair paint and coatings

XiangYuan chemical waterborne automotive paint water-based paint USES the advanced environmental protection technology products, by the waterborne polyurethane polymer copolymer, various environmental protection paint, metallic paint, pearl effect pigments, pure water and a small amount of film forming additives such as room temperature since the dry coating system, the system has more than 30 varieties, every mother, more than 20 metal and pearlescent masterbatch, 10 accessories, altogether;More than 60 water-based products, can be widely used in cars and other kinds of transport and the application of high finishing requirements.

1 XiangYuan chemical characteristics of the car paint coating (color, efficiency, cost)

(1) environmental protection: low VOC content (185 g/L), completely conforms to the requirements of environmental protection, low odor, no vapor, less paint mist;

(2) color: the color is easy, dry and wet film color difference, color is simple, no difference color mixing method, easy to learn, such as

Fruit have oily based color mixing, color mixing with proper training, can independent operation water-based paint palette within two weeks;

(3) covering power, covering significantly higher than that of oil paint, water-based paint spray, 1.5 just equivalent to 50% ~ 75% oil paint film

Thick cover can achieve the same effect, time saving material;

(4) construction: can be used for coating or separation coating, construction is convenient, the construction method and paint no difference, the painters

Easy to accept, but also easy to train new the painters, but also has better than oily coating metal particles are arranged and better visual

The effect;

(5) drying: drying way is diversiform, drying speed control, can make the drying speed by blowing or proper heating with oil

The fairly;

6. Appearance: because after blowing or drying, dry degree has reached 80% ~ 95%, of the varnish coat after phase

Capacitive better, and the water-based paint has better metal particles are arranged, than solvent-based paint has better visual effect.

7) storage conditions and time limit: with plastic or not react with water seal tank packing material, 5 to 35 ℃ condition (to avoid light and heat

Direct) can be stored for two years;

Today technology, equipment, and environmental requirements: a bit higher than the oil paint, but compatible with oily standard workshop equipment, transfer from oily water

Spray room only appropriate improvement in cleanliness, ventilation conditions, with special water-based paint spraying tool, usually from oil to water

All process, about two weeks or so to complete;

Note 2

1) must be the primer before coating grinding and clean (dry grinding: 400-600 # sandpaper, wet milling: # 800 or more fine sandpaper);

(2) use water-based paint tools and containers should be not react with water to material (stainless steel, plastic, etc.) or have the right within the coating

Processing;

(3) before color mix on color mixer, has mixed paint should be immediately stir well;

(4) film drying speed depends on the construction of environment temperature, humidity and air velocity;

(5) has been added blending of thinner paints out that day as far as possible;

6 spraying immediately after the completion of all cleaning spray gun and apparatus, in order to prevent the fouling, it is recommended to use a separate water spray gun cleaning machine,

Clean with deionized water;

All landowners wastewater treatment: water-based paint paint waste and waste water to the oily segregated and handled separately, waste water directly into

Daily sewage, should add water-based precipitant to solid-liquid separation, pay has green credentials for processing center centralized processing.

XiangYuan chemical group will continue to innovation, take the customer as the center, customer service, customer satisfaction has been our pursuit!

XiangYuan Chemical Group, WelcomeYou!

中文版

中文版 English

English